How Does Flow Switch Works in Unsafe Conditions?

Flow switches help monitor flow and send trip signals to other instruments like the pump to prevent damage. You can use these devices to determine the flow of gases, steam, and liquids. A flow switch can as well trigger an alarm and provide protection when needed. All flow switches are flow meters, but not all meters are switches. However, they all can regulate flow.

The flow switch has a valve body, sensing instrument, and a switching unit connected to the pipe. The valve in control helps to sense the flow of liquid or gas. The switching team will then read the sent signal, increasing or decreasing the electrical signal. This switching unit also can turn a pump or valve on and off to help maintain a correct flow system.

You can also use these switches to regulate features of the flow like volume speed and pressure, and they will also adjust changes that take place. Also, ensure that you use flow switches to find problems in the system.

How Flow Switches Work

Flow switches work by using a rip motion to a pump in a system. It sends the sign that will show the pump to turn on or off. This device helps to give protection and circuit cooling if the flow rates are too high or low. A flow switch can serve many functions, and you can as well use it in many applications. If you want to regulate the flow of fluids or protect the pump from damage, you will need this device. Discharge is usually the energy or physical motion of gas, steam, or liquids in a pipe that triggers the flow switch. When there is no flow, the velocity will drop or stop altogether. The controller will go back to normal in either case.

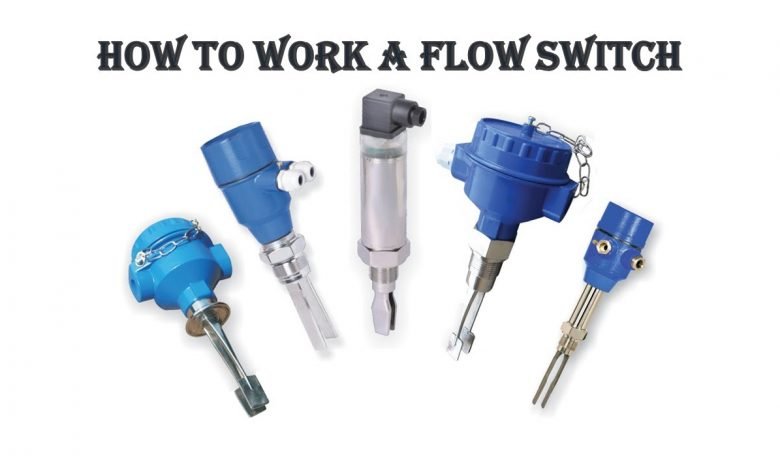

Types of Flow Switches

You can categorize these switches by either flowing media or the measurement type. This means that you can mix the types like volumetric flow meters.

· Gas flows are used to measure the flow of gases and steam. They are mainly used in HVAC applications.

· On the other hand, liquid flow switches are used chiefly for media such as water, lubricants, chemicals, and slurries. You can use them in a broad category of applications.

· Volumetric flow switches help in measuring gases and liquids. The measurements usually base on volume per unit time. That is, in cubic feet per unit time.

· Velocity flow switches help in measuring the flow of moving media. The measurement usually performs in terms of velocity. That is feet per minute.

Applications of Flow Switches

The uses of flow switches are:

· Pump staging.

· Pump or valve failure.

· The detection of flow or blockage.

· The protection of the flow.

You will find them mainly in reservoirs and tank storage systems. This is to keep the tanks at the proper levels and the pipes to ensure that the media flow in the pipe continues. You will find flow control devices in commercial and large buildings for HVAC systems.

The Specifications of Flow Switches

Essential working and performance considerations are;

The media type- when you are looking forward to purchasing a flow switch, ensure that you consider the kind of media that it will be exposed to. An instrument that measures water is usually made of bronze or brass. This is because these metals can resist corrosion, rust, or breakdown. You can use plastic in applications that are not prone to freezing or expanding in hot conditions. Plastic is lightweight but is durable and can resist rust.

The diameter of the pipe- the diameter tells the size of the line in a system. Ensure that the switch fits well in the bar, so ensure that you consider this before buying a button. These devices are basically use for heat exchanger devices.

The operating pressure should also consider the maximum pressure head of the process media that the switch can withstand.

Conclusion

Flow switches are essential devices when it comes to flow regulation. These devices are also available in many models, and each works differently. Therefore ensure that you select the one that is right for your applications. Also, ensure that you install it correctly in your pipe if you want to get accurate results.